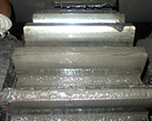

When Tecsia Lubricants went for a site inspection, the team of Certified Lubrication Specialists (CLS) found severe wear patterns such as pitting, spalling and scoring on the roller surfaces. The surfaces were no longer smooth and had been filled with craters and holes. It was concluded that the previous lubricant built up at the sides, illustrating that there was minimal lubrication at the contact surfaces. Inadequate lubricant as well as a lack of lubrication caused the rollers to suffer such damages.

As for the open gear drive, deep scoring and scuffing marks were found on the surfaces too. Little to no protection were found at the meshing surfaces. As a result, operating load was not evenly distributed. Due to all these damages, the applications’ lifespan are shortened due to the unfortunate, irreversible defects.

The corrective action is to apply TACBECON® SOG 3000A for immediate protection and, to slow down the deterioration rate on the roller and gear surfaces. TACBECON® SOG 3000A is recommended for the trial, because it provides high base oil film strength, high extreme pressure performance and advanced solid lubricant additives. These properties offer exception protection to the sliding surfaces.

The trial was observed over a month’s period. Tecsia Lubricants’ CLS reported positive results! The lubricant adhered strongly to the surfaces and the solid lubricants was evenly distributed across the surfaces and filled into the craters and holes. Operating temperature stabilised and production became more efficient. The trunnion rollers and open gear drive now have a consistent supply of lubricant that facilities crucial protection for optimal production.